Preventing a Power Surge

Scope of the Hazard

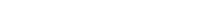

The probability of your facility experiencing a power surge is 100%. A 17-month study done by IBM in 49 cities across the country found that an average of 128.3 disturbances happened in each monitored building every month, equating to an average of over 4 power surges per day. A serious power surge can damage your business equipment. Electrical industry experts estimate that businesses alone lose tens of billions of dollars every year from power quality issues. And, while it is unknown how many fires result from power surges, electrical issues in buildings cause over 140,000 fires each year, resulting in 400 deaths, 4,000 injuries and $1.6 billion in property damage. Surge protection addresses both power reliability and power quality. A power surge takes place when the voltage in a building’s electrical wiring spikes to 110% or more above the normal operating voltage. Power surges are so brief they are measured in nanoseconds, microseconds, and milliseconds, but can cause considerable damage to equipment. Minor electricity fluctuations (either up or down) are normal in any electrical system. Figure 1 shows what a power surge would look like on an AC electric power waveform.

Figure 1

AC electric power waveform

Power Surge Causes

Between 60-80% of all power surges originate inside a building. About 20-40% of power surges are created outside a building. The most common cause of power surge inside a building is from larger electrical equipment being turned on and off throughout the day. Under these conditions lights will flicker, equipment will shut off, and computer equipment will experience operating errors or data loss. The most common cause of power surge outside a building is from utility grid switching where utility companies re-route electricity on the grid.

Internal Sources

- Equipment load cycling: This occurs when equipment is switched on/off during everyday use. Examples of equipment that create internal power surges are printers/copiers, robotics, variable frequency drives for electric motors, air conditioning and refrigeration units, electric motors, capacitor banks, production equipment.

- Short circuits and loose wire connections

- Damaged electrical wiring

- Line noise - Electronic Magnetic Interference (EMI) and Radio Frequency Interference (RFI)

External Sources

- Utility company excavation activities (strike an underground power cable)

- Lightning (aka oscillatory voltage transient)

- Faulty utility wiring

- Distribution transformer failure

- Power line detachment or contact with one another

- Birds or squirrels contact power lines (short circuit)

- Power outages

- Utility grid switching to re-route electricity from power lines

- A sudden increase in electricity usage by a nearby commercial building

What type of equipment is affected by a Power Surge?

Electronic equipment such as computers, programmable logic controllers (PLCs), motor control center (MCCs), data servers, TV/video monitors, security systems, printers, and the telephone system. This type of equipment offers electricity the path of least resistance for a power surge. Much of this electronic equipment also provides data storage and transmission to other electronic devices, such as routers and servers that can be compromised from the damaging effects of a power surge.

Protection from Power Surges

What is a Surge Protection Device (SPD) and how does it operate?

There is no way to predict when a power surge will occur, but there is a way to protect your building’s wiring, equipment, and business income from downtime caused by an unavoidable power surge using an SPD. It is an electrical device that smooths out spikes in electricity to prevent damage to electrical equipment, especially electronic equipment downstream. An SPD is a power management device that has a positive effect on the power quality and reliability of equipment used by a building.

How are power surges prevented?

The SPD absorbs the power surge energy and safely reroutes it to the facility’s electrical grounding wire, before it has a chance to reach equipment in its electrical path. SPDs do not provide 100% protection, but other than surges from direct lightning strikes, they will adequately protect your facility when properly

installed.

Layering Surge Protection Devices

The Advantages

Layering of surge protection devices is a comprehensive approach that involves the installation of multiple SPDs in order to address power surges that are created both inside and outside your building.

Layering surge protection devices offers more protection from power surges. For example, if you have your computer plugged into a power strip with built-in surge protection, you are only protecting the computer from external power surges. In order to protect your computer from internal power surges, the same computer would also need SPDs installed at the main electrical panel and the branch circuit panelboard supplying electricity to the computer.

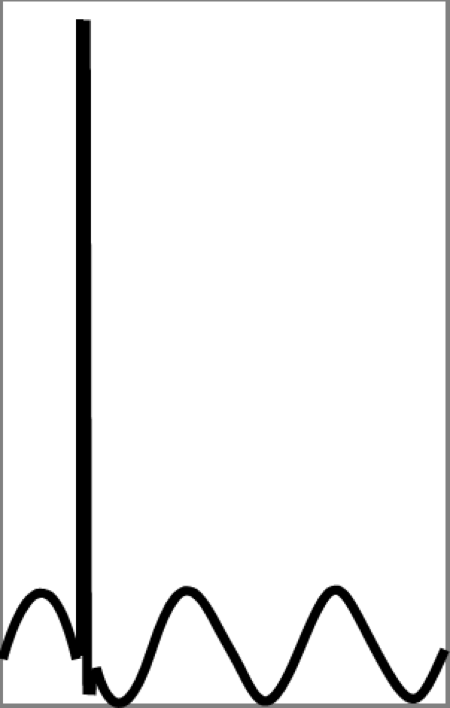

Figure 2

A more robust type of SPD installed at the main electrical service panel and in branch circuit panelboards.

Types of Power Surge Devices

The layered approach involves the incorporation of all three types of surge protection devices in order to maximize the entire facility’s protection against power surges.

Type 1:

This type of SPD is designed to handle utility grid switching and other external power surges, and is usually installed at the line side of the main incoming electrical service panel. This type is usually referred to as Building Entry SPD or Whole Building Surge Protection. This offers protection to all equipment in the facility including the main electrical service panel and equipment on branch circuits.

Type 2:

This type of SPD is designed to handle both internal and external power surge sources. It is installed in panel boards to protect branch circuit wiring and equipment powered on a branch circuit. It is installed between the load side of the main electrical service panel and the panel boards scattered throughout the building connected to specific equipment. It is also called a Secondary Surge Suppressor. This type of SPD offers protection to all equipment connected to the load side of the main electrical service panel or branch circuit panel board such as MCCs, PLCs, variable frequency drives, equipment monitoring system, lighting wire and security systems.

Type 3:

The most common type of SPD, Type 3 are designed to protect electronic equipment that is very sensitive to power surges. This equipment is plugged directly into the SPD, which is usually a typical power strip that protects individual equipment at the load side. It is also called a Point-of-Use SPD and offers protection to all equipment plugged into a power strip including computers, printers, smartphones and other peripheral electronic devices.

Choosing and Installing an SPD

The SPD should have a UL 1449 3rd Edition listing on its label. UL 1449 is the most well-known industry standard for safety of surge protection devices. Be aware that some SPD manufacturers label products UL tested or UL approved and this is not the same as being UL Listed.

When selecting, specifying, or comparing SPDs, it is important to understand the ratings that are most important. The key SPD ratings to consider are:

Nominal Operating Voltage (Vn):

This is the normal operating voltage of your building’s electrical system. The SPD should match your building’s supply voltage. Rated in Volts.

Clamping Voltage (Vpeak):

In simple terms, it is the amount of electricity over normal levels that an SPD will divert to earth through the building’s electrical grounding system. Higher quality SPDs will have a lower clamping voltage value. When the SPD reaches the clamping voltage, it blocks electricity from flowing through the SPD and into equipment, including electronic devices. Rated in Volts.

Maximum Discharge Current (Imax):

This is the main overall capacity rating of the device and is a predictor of how long an SPD will last in a given operating environment. The higher the rating, the longer the life of the Metal Oxide Varistors inside the SPD. Similar to a car tire, the thicker the tread and the more durable the rubber, the longer the tire will last. It is never intended that an SPD will be subjected to the Maximum Discharge Current. Rated in kA.

The electrical contractor will evaluate your facility’s electrical distribution system, and should select SPDs with ratings that meet the specific installation requirements. Do not install an SPD in an area where it would be covered with equipment or storage that will limit or prevent air circulation. In addition, the SPD should be rated for the operating environment where it will be located, considering factors such as moisture/humidity, dust, corrosive atmosphere, flammable vapors, and extreme ambient temperatures (very hot or very cold). Indoor SPD installations should use at least an NEMA 3 type enclosure, and outdoor installations should use at least an NEMA 4 type enclosure.

Guidance for Your Facility

Knowledge of Earth Ground Resistance:

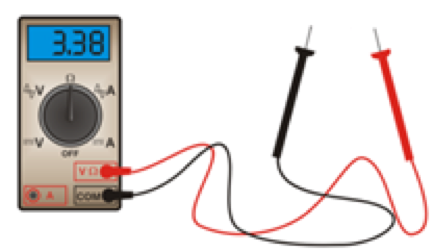

A properly working electrical grounding system is the first step to an effective SPD. The integrity of the existing electrical grounding system is critical before installation of an SPD because power surges are diverted to earth through the facility’s electrical grounding system. Therefore, the importance of a low-resistance grounding system for the facility can’t be overstated. Anything less than a low resistance grounding system will cause power surge energy to flow back into facility, with potentially adverse effects. Ground resistance is often measured by an electrician using an ohmmeter as shown in Figure 3.

Figure 3

A checklist to consider when choosing an Installation Contractor:

- Does the contractor test incoming power quality before SPD installation?

- Does the contractor test grounding system resistance at no charge?

- Does the contractor have experience with installing SPDs for your type of electrical service and your class of business?

- Are references and documented project examples provided?

Cost:

Depending on the existing power quality of the building, working environment, installed location of the SPD, and isokeraunic activity (avg number of lightning strikes/year), SPDs can cost as little as $40 for a small commercial business and can go up to $7,000 for larger facilities. There are also SPDs that can be installed at the electric meter and rented from a local electrical provider for a very low monthly fee that is added to the building’s monthly electric bill.

Business Continuity

We know power surges can cause damage to business equipment, as well as property when it results in an ignition source for fire. This often leads to unscheduled down-time and interruption of business operations, which could be more costly than the physical damage. Business continuity can be affected in many ways:

- Rescheduling of work

- Reconfigure other production/processing equipment to temporarily pick up the workload of the damaged equipment

- Equipment throughput errors (as a result of damaged electronic components) leading to a higher rejection rate of the end product

- Missed contract deadlines

- Reproduce or recreate lost data

- Missed opportunity to bring on new customers

- Damaged reputation

- Rework to meet product quality demands

- Lost customers

- Late deliveries

- Idle workers

Be proactive! Develop a plan, and execute! But most of all, have a wonderful holiday season!

For additional Loss Control tips please join our LinkedIn Group and visit BerkleyAssetProtection.com.